The Process Behind Cinnamon

1. Plantation

Beginning from the foothills of Mount Kerinci and Padang locale in West Sumatra, our cinnamon plantation are regularly planted by local farmers and villagers. This region is producing up to 75% of the world’s cassia. The trees are planted in lines and harvested every each ten years. It grows up naturally and organically without any pesticides, fertilizers or other chemicals and far away from pollution.

2. Harvest

Firstly, trees are chosen to be cut depending on their age. The bark is isolated on special-area after the trees have been cut to guarantee the greatest freshness.

The external bark is removed, sorted by thickness and after that stuffed into bunches.

3. Sorting Raw Material

All incoming raw material will be sorted into each grades by the expert. Each bale of raw material brought by farmers of local trades mostly consist of 3 or 4 grades.

4. Drying Phase

The cinnamon barks will be dried under direct sunlight for 4-5 days.

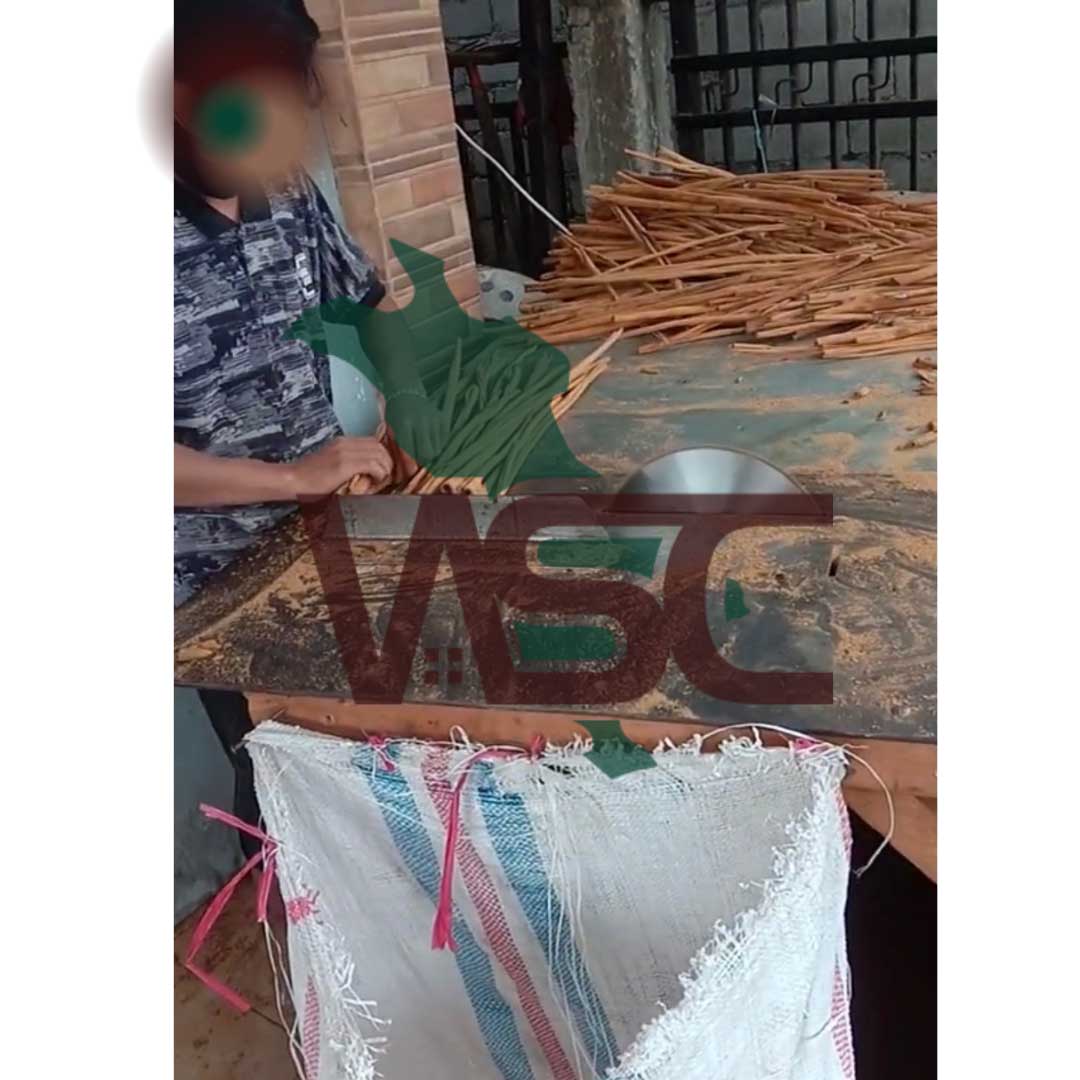

5. Cutting Process and Final Sorting

Cutting cassia will be sorted again for the length & cleanliness by pounding the sticks into wooden pad in order to make small insects and dust inside roll of cassia will drop out. Finally, finished products will be put in storage room before being brought to port of loading either for cutting cassia, stick cassia of broken cleaned cassia.